Hydraulic control valves are integrated components in hydraulic programs, providing as the key regulators of fluid movement, pressure, and direction. These valves enjoy an essential role in a wide array of applications, from professional equipment and structure equipment to aerospace and automotive systems. The basic concept behind hydraulic get a grip on valves lies in their capacity to manage the movement of hydraulic substance inside a program, permitting specific get a grip on and treatment of numerous components.

One of many primary features of hydraulic get a handle on valves would be to manage the force in just a hydraulic system. Stress get a grip on valves, such as for example aid valves, ensure that the force stays within secure operating restricts, stopping potential harm to sensitive and painful components. That is particularly essential in programs wherever sustaining a certain stress stage is critical for optimum performance and safety.

Online get a handle on valves are another crucial category of hydraulic control valves. These valves determine the direction of substance flow within the system, enabling the managed motion of hydraulic actuators. Whether it’s the expansion or retraction of a hydraulic cylinder or the rotation of a motor, online control valves govern the routes by which hydraulic water flows, dictating the action of the related machinery.

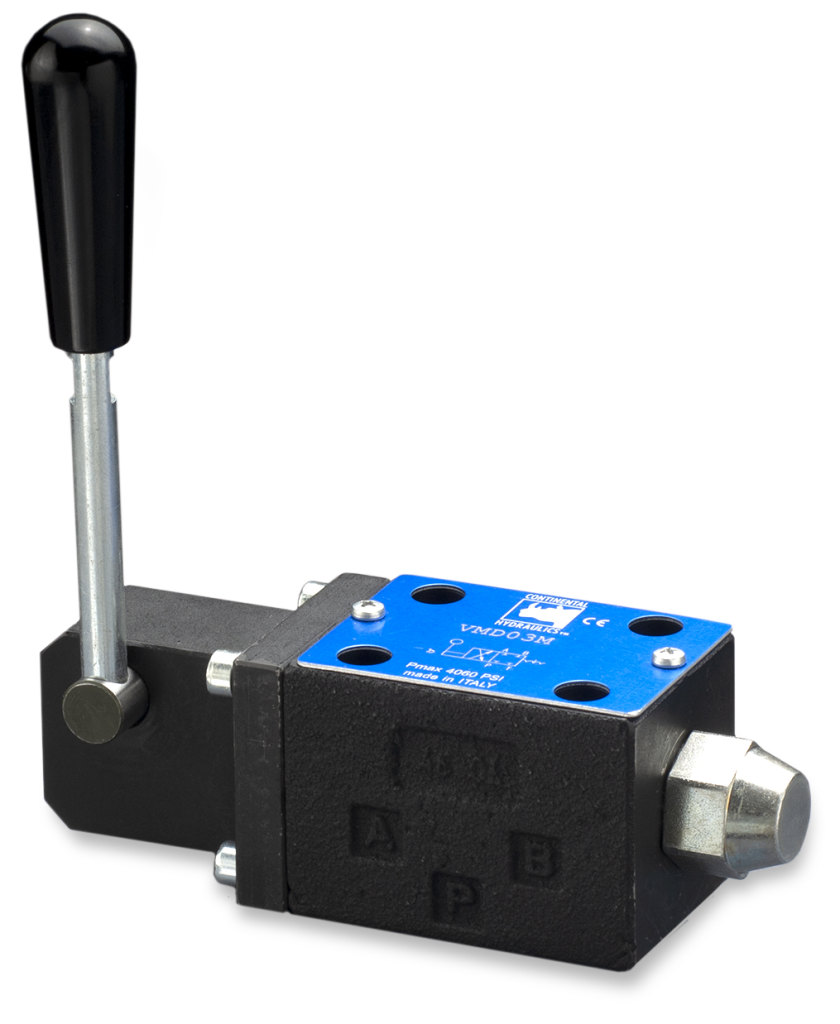

Hydraulic get a handle on valves were created with a variety of get a handle on systems, including information, technical, and electro-hydraulic. Handbook valves enable hands-on get a handle on, physical valves react to external forces or mechanical inputs, and electro-hydraulic valves influence electrical signs for precise and computerized control. This variety in control alternatives makes hydraulic programs flexible to various working needs and consumer preferences.

Efficiency is really a important consideration in hydraulic techniques, and hydraulic get a grip on valves play a pivotal position in optimizing performance. Proportional control valves, for instance, permit fine-tuned adjustments to liquid flow rates, permitting precise control within the speed and force of hydraulic actuators. This degree of control promotes over all process efficiency, reducing energy waste and ensuring maximum operation.

Along with their major operates, hydraulic get a handle on valves donate to process safety. Pressure relief valves act as fail-safes, guarding the system from overpressure and potential damage. The sensitive nature of these valves ensures that, in the event of a pressure spike, hydraulic substance is diverted properly, avoiding catastrophic problems and safeguarding equally the equipment and personnel.

The preservation of hydraulic get a handle on valves is essential for maintained system performance. Normal inspections, washing, and lubrication are essential to prevent use and split, leaks, and different problems that may compromise the functionality of the valves. Appropriate maintenance not just extends the life of the valves but also ensures the stability of the whole hydraulic system.

Invention in hydraulic get a handle on valve technology continues to advance, with the integration of electric and clever technologies. Electronic get a handle on units (ECUs) help specific and programmable get a grip on around hydraulic techniques, opening ways for automation, distant monitoring, and predictive maintenance. As industries shift towards Market 4.0, the role of hydraulic control valves hydraulic control valves becomes increasingly critical in producing interconnected and intelligent hydraulic systems.

To conclude, hydraulic get a handle on valves would be the unsung people of hydraulic systems, giving the required control and regulation for the effective function of varied equipment and equipment. Their flexibility, accuracy, and factor to process safety cause them to become fundamental in industries wherever hydraulic energy is harnessed for an array of applications. As technology remains to advance, hydraulic control valves will probably play an even more advanced position in shaping the ongoing future of hydraulic systems across diverse sectors.